PRODUCT

MONITECH

ARC, SPOT Welding quality monitoring system

WET-3000A, WET-4000S, WET-3000T

- For 18 years, continuous technical support and after-sales service have been provided worldwide in the USA, China, Europe, Brazil, India, Turkey, and more, using the world's top-level measurement equipment.

- Process loss reduction > Process stabilization > Defect rate reduction > Cost savings effect.

- Offering various system configurations tailored to customer needs (single, multi-control, etc.).

- An optimal system for SQ, 5-STAR, and HIVIS assessment.

- Capable of measuring AC, 3-phase rectifier DC, inverter DC, and capacitor DC.

Video

Key functionsand features

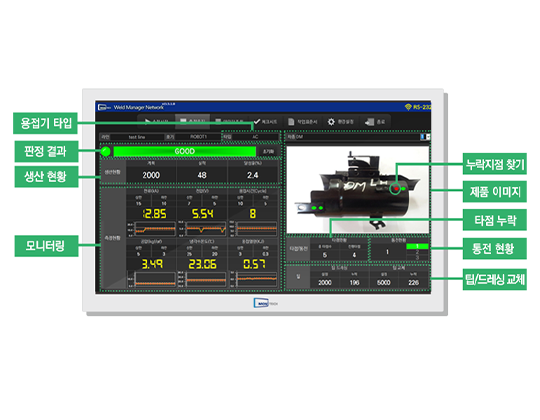

- Providing a real-time welding quality estimation (F/Proof) production management information system.

- Production history retrieval, Cp/Cpk analysis, work standards, daily checklists, and automatic report generation.

- Features for measuring and managing current pass separation (SPOT) and patented technology for initial high-frequency and high-voltage interruption (TIG, PLASMA)

| ARC Welding | SPOT Welding | TIG & PLASMA Welding | |

|---|---|---|---|

| Model | WET-3000A | WET-4000S | WET-3000T |

| Management items | Welding current/voltage, gas flow rate, gas remaining (optional), welding time, tip replacement interval. | Welding current/voltage, welding time, air pressure (pressure), coolant temperature, heat input, welding time, tip/dressing replacement interval. | Welding current/voltage, gas flow rate, gas remaining (optional), welding time, tip replacement interval |

| Measurement Range | AC, DC, inverter DC(Max. 2000A) | AC, DC, inverter/condenser DC (Max. 200kA) | AC, DC, inverter DC(Max. 2000A) |

| I/O (Input/Output) |

Max. of 31 I/O provided(by unit, model, bead) | Max. of 15 I/O provided (by unit, model, point, pass) | Max. of 31 I/O provided(by unit, model, bead) |

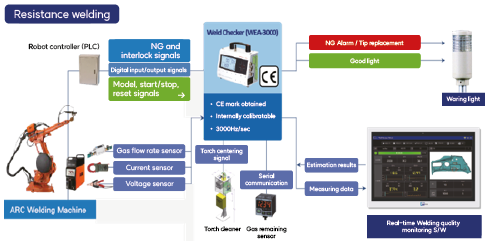

System configuration diagram